By Brad Ocock

Photography: Brad Ocock

|

| |

Think back to, oh, say August. Remember how hot that cruise was on Saturday? It doesn’t matter which Saturday, because in August, they were all hot. Same with June and July. Yeah, there’s nothing like peeling yourself off of your vinyl seat covers and actually being glad to get out of the car because you can go stand in the shade (instead of being trapped in that greenhouse we call a passenger compartment) and enjoy what’s passing for a breeze. Plus the back of your shirt will dry out, which is always nice.

You know you’ve been there!

The Paddock Project Charger was originally equipped with air conditioning, which owner Mike Paremsky was adamant about keeping. However, he wasn’t particularly thrilled with the factory system for one reason: the compressor.

First, the compressor is a dinosaur, and weighs nearly as much as one of the ancient reptiles. The factory RV-2 compressor is constructed of cast iron and weighs in at nearly 45 pounds. Because it was the original unit, the compressor would also have to be rebuilt to perform. Mike also wanted to convert the system over to R134a refrigerant for ease of maintenance, though as we’ve discussed in previous stories, this is easily accomplished during the rebuild process ("Ice Age Returns," Sept., Oct., Nov., 1999). Finally, its design isn’t the most efficient, with one of the results being a parasitic loss on the engine of about 12-15 horsepower. Heavy and horsepower robbing--not things you generally want on a performance vehicle, particularly on the nose of the vehicle.

We’ve worked with Classic Auto Air in Tampa, Florida, on other A/C system restorations and conversions, and as luck and timing would have it, they had just developed an A/C compressor retrofit kit that replaced the stock RV-2 compressor with a smaller, lighter and more efficient Sanden air compressor.

|

| |

The crux of their conversion is a pair of brackets that allow the Sanden compressor to mount in the stock location, even using the factory-length fan belts for the compressor clutch and the original hard refrigerant lines. This is truly a remove-and-replace deal that will net you a more efficient compressor with a parasitic loss of about three horsepower, works at a much higher rpm than the stock unit, is close to thirty pounds lighter than the iron pump, and is more attractive in the engine compartment due to its smaller, less clumsy design and aluminum housing. For those with really detailed engine compartments, Classic Auto Air also stocks fully polished aluminum Sanden compressors.

Classic Auto Air also supplied us with brand new, correct reproduction A/C hard lines and restored our original plenum box. They checked and inspected all the other components of the system, replacing what was needed.

The system is supplied with the a new thermostat and expansion valve, so there are no other components to buy: just install the system and have it charged by a certified technician.

And if you’d rather retain the original compressor, you want to concours restore your entire system, or you want to add A/C to a car that didn’t originally come so equipped, Classic Auto Air can supply you with everything you’ll need to cool the cabin.

|

| |

| Article Sidebar: |

Not Cool Refrigerant |

| |

| Article Source: |

| Classic Auto Air |

|

|

|

|

| |

|

| |

|

| |

|

|

|

|

|

|

Click to enlarge photo

|

|

|

|

|

Click to enlarge photo

The stock A/C compressor: It gets the job done, but the technology behind it is close to 40 years old. Itís heavy, not the most efficient, and itís bulky and none-to-attractive in a modified engine bay.

|

|

|

|

|

Click to enlarge photo

Al Sedita, owner of Classic Auto Air, did the installation on The Paddock Charger. He began by removing all the underhood components, including the original hard lines, expansion valve, filter/drier and compressor/boat anchor.

|

|

|

|

|

Click to enlarge photo

Al showed us two things that are very common on old A/C systems, even those on cars that have been restored: the first is the use of common hose clamps. This is a big no-no, as the system is under pressure and hose-clamped couplings can fail.

|

|

|

|

|

Click to enlarge photo

The other significant and very common problem is weak and corroded hard lines that have been repaired by brazing or soldering. Itís common for original hard lines to rust through, especially behind the water bottle (where moisture often gets trapped) and where the line runs behind the battery (where acid fumes can eat through the steel tubing). Classic Auto Air manufactures a complete line of exact reproduction lines and fittings, so there is no longer a need to try and rescue your originals.

|

|

|

|

|

Click to enlarge photo

This bracket is manufactured by Classic Auto Air specifically to mount a Sanden compressor to big-block Mopar applications in the factory location.

|

|

|

|

|

Click to enlarge photo

It bolts to existing water pump housing bolts and goes right in place of the original compressor bracket.

|

|

|

|

|

Click to enlarge photo

This chunk of billet steel, also designed and produced by Classic Auto Air, mounts the back of the compressor to an existing threaded hole in the cylinder head (the one the negative battery cable mounts to) with a counter-sunk cap screw. So now the front and rear of the aluminum compressor are solidly mounted to the engine. The negative battery cable can be grounded using either an intake manifold bolt, motor mount bolt, or anywhere else it will get a good ground.

|

|

|

|

|

Click to enlarge photo

Hereís what the back mount for the compressor looks like installed. The little billet piece of steel is well thought out, very simple, and very solid.

|

|

|

|

|

Click to enlarge photo

After the compressor is mounted...

|

|

|

|

|

Click to enlarge photo

...itís time to replace the hoses, lines, filter/drier and expansion valve, all of which install in the factory locations and look like factory pieces.

|

|

|

|

|

Click to enlarge photo

Hereís a detail shot of how exact Classic Auto Airís hard lines match the factory originals. This hole in the top of the radiator core support is a factory hole on A/C equipped cars; the original lines going to and returning from the condenser run on each side of this hole, and a small bracket with a sheetmetal screw holds them down.

|

|

|

|

|

Click to enlarge photo

CAAís reproductions fit perfectly. The crimped hose ends are also exact duplicates of Chrysler originals, for you concours guys.

|

|

|

|

|

Click to enlarge photo

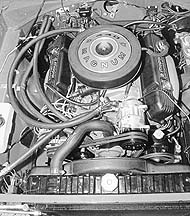

Hereís the nearly-finished installation. Mike wasnít done detailing the car and found out he needed a new heater core, so the final positioning of the heater hoses, etc. hasnít been done at this point. However, you can see here that the rubber lines for the compressor are going to run in a clean, orderly route, giving a factory-like appearance. Also note that both original-length fan belts are retained to drive the compressor clutch.

One difference, however, is that both hoses come off the back of the Sanden compressor and run to the passenger side of the car, rather than one to that side, and the other to the driverís side as originally equipped with the old RV-2 compressor. This configuration eliminates the hard line running behind the battery and crossing over the top of the radiator core support. This more direct routing, coupled with the Sandenís smaller body and aluminum finish, gives the engine compartment a less cluttered, much cleaner appearance.

|

|

|

|